|

Step zero

A decent workshop helps. From left to right: lathe, mill, workbench, framejig and behind the circular saw on the right you can just about see the alignment table |

|

Step one

Start with a drawing with all angles and lenghts. A computer is very convenient here, this drawing was made in seconds with Radicalc |

|

Step two

Get all the tubes and bits together. This is a MTB set with slalom seatstays |

|

Step three

-start with slotting the stays |

|

Step four

- braze in the dropouts and clean-up

|

|

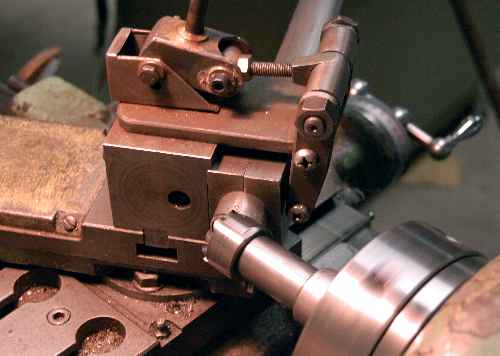

Step five

- machining the chainstays to the exact lenght |

|

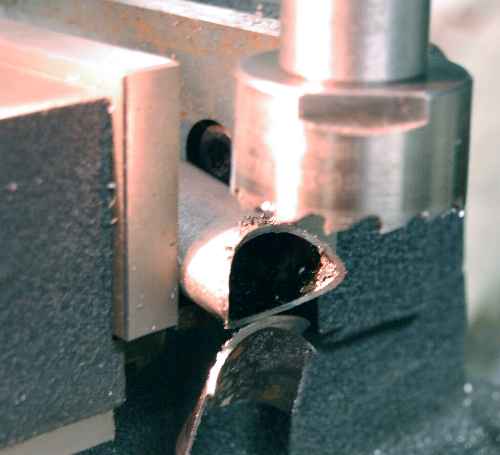

Step six

- machining the frametubes with a holesaw |

|

Step seven

-drilling holes for waterbottle-bosses while you still have access |

|

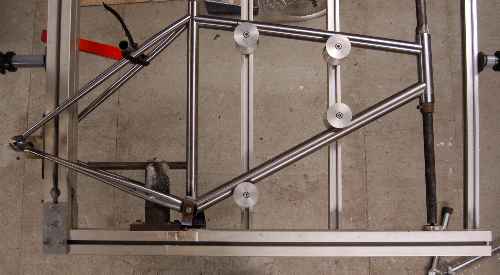

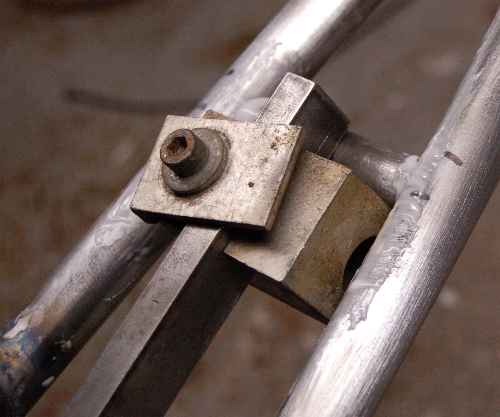

Step eight

- put the tubes in the framejig and check for fit |

|

Step nine

-ready for degreasing, fluxing and brazing |

|

Step ten

- Presto we have a frame, but still a lot of finishing to do |

|

Step eleven

- filing and sanding gives a result! |

|

Step twelve

- finally fit all the small bits and bobs, as cablestoppers, cantipivots, brakebridges etc |

|

Step thirteen

- raking the fork |

|

Step fourteen

- final alignment check |

|

Step fifteen

-all it now needs is a bit of paint |