| Son hubdynamo's are extremely

reliable, but problems could occur. With these pointers you should be

able

to identify and rectify most problems

No lights

Usually the fault lies with

the wiring, not the dynamo. Just as with any other lighting setup a

methodical

search helps. Disconnect the rear light first, if the headlight now

works

normally, you have probably swapped the leads to the rearlight causing

a short..

If this doesn't work remove

the leads from the dynamo. Give the wheel a spin and shortcircuit the

terminals

with a coin or key. If you get sparks and the wheels slows down

measurably

the hub is ok.

Reconnect the wiring and

spin the wheel again. If flipping the switch doesn't do anything you

have

an open circuit (look for blown bulbs or broken connectors), if the

wheel

slows down as short circuited on one or both positions of the switch

you

again have a short circuit (incorrect wiring, frayed cables).

If the dynamo fails to deliver

current (easily checked by giving the wheel a spin and shortcircuiting

the terminals with a screwdriver: sparks should be visible) the

internal

wiring in the dynamo could be faulty. This can be damaged if some moron

er.. ill advised individual tries to adjust the non-adjustable

bearings,

or by riding around with a loose skewer. This is has to be repaired by

a SON approved technician (eg the importer of factory)

E6

Most frequent mistake is

putting the black switchring back on reversed. The magnet won't reach

the reedswitch and the light will remain dark.

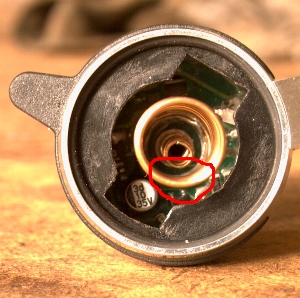

With the E6 it is possible

for the central contact-spring to short circuit against the spring

holding

the bulb in place in the reflector. My guess is this can happen when

the

bulb slips out of the reflector during insertion. Carefully bend the

spring

back with a ballpoint refill or similar.

No front light (classic

round Lumotec only):

The contact-lip (which contacts

the back of the bulb) could be bent backwards. This can happen if you

reposition

the light frequently with the mounting screw done up tight. To fix open

the Lumotec, remove the coil spring, bend the central contact

forward

a few millimeters and reassamble. Stop readjusting the angle of the

light,

or loosen the screw first.

Dim frontlight

Bulbs only have a lifespan

of around 100 hours (a household bulb = 2000-3000hrs!) With age the

filament windings

could weld together and short out, which decreases the light emitting

surface.

Replace the bulb for full power.

No rear light

The Son has no connection

to earth. If you use single wiring to the rear light the returnpath is

made up by the connection through the frame to the front light. Ensure

that both components are securely connected to the frame.

No front and rear light

Lights usually have a connection

to earth. If you use double wiring to connect the rear light to the

front,

do not get the wires mixed up. If you connect the wires crosswise, the

dynamo will be shortcircuited.

Frequent front bulb failure.

Mean time to failure for

a bulb is around 100 hrs, and even less (30-50) for the fast crowd. If

you ride a lot that could mean several bulbs a year. If the bulbs fail

a lot sooner, a failed or disconnected Z-diode is usually the culprit.

With old Lumotecs the diode sometimes makes poor contact, with the

Lumotec

Senso the diode could melt its connection to the circuitboard.

If you use a headlight only,

without connecting a rear light, change the bulb to one rated 3 watts.

Fitting the headlight to

the unsuspended part of a suspensionfork is very hard on the filament

and

will shorten bulblife.

Irregular & spotted beam

This is usually caused by faults of the filament. With old bulbs the

winding could have shortcircuited, causing irregular lighting. With

cheap bulbs the filamentposition could be out of specification, moving

the light source out of focus

The properly defined filament is on the left, the 'cheap' bulb is on

the right. Note the much more widely spaced filament windings

Rear light bulb failure

This is usually caused by

the high voltage caused by a failed frontlight together with a

dis-functioning

Z-diode. Check the headlight if this happens.

Rear light goes on late

or not at all

A frontbulb with shortened

windings has a lower resistance, causing the voltage to drop (the

Dynamo

is a currentsource) If the voltage is too low LED lights with

standlight

will not function well. Replace the front bulb to restore light at both

ends

Noisy hubdynamo

Bearing play

Newly installed bearings

have zero play. With use the axial and radial play could increase to

0.01-0.02mm.

This will result in approx. 0.2 mm sideplay at the rimface. This cannot

be adjusted out and is normal for this kind of bearing. If you find a

lot

more play the bearings are probably damaged and you should return the

hub

for service. Never try to adjust the bearings, you'll only succeed

in severing the electrical connections and voiding the guarantee!

Rattling noises

These are usually caused

by an unsufficiently tightened skewer. Check that the OLD of the fork

is

100 mm (XS excepted), and that the dropouts are parallel and that the

skewer is really tight

Irregular grinding noises

This could be caused by

sand in the labirinth seal, or a fragment of the very brittle magnets

running

around in the hub. This isn't critical and should disappear with

use.

Regular grinding noises,

difficult turning or locked axle.

This could be caused by

a locked dynamo, not by bearing failure. The interior is well sealed.

If

-salt-water manages to find it's way inside, it won't come out easily.

Thus the hub could freeze solid, or rust particles could get jammed in

the narrow crevice between stator and rotor. Do not keep riding this

dynamo

but send it in for service.

SON's old type (with black centersection

prior to '99)

We have never imported this

type which needs to be unspoked from the wheel before it can be

serviced.

Son guaranteed the hub for three years after purchase, but it can be

sent

in just like the others for service.

This also applies to the

hubgenerators Wing 1,2 en 3 by Union and Marwi: these are based on a

design by and can also be

repaired

by Schmidt.

|